Refrigerant plant Room Detection and Monitoring system

Gas Detection Solutions for refrigerant plant room

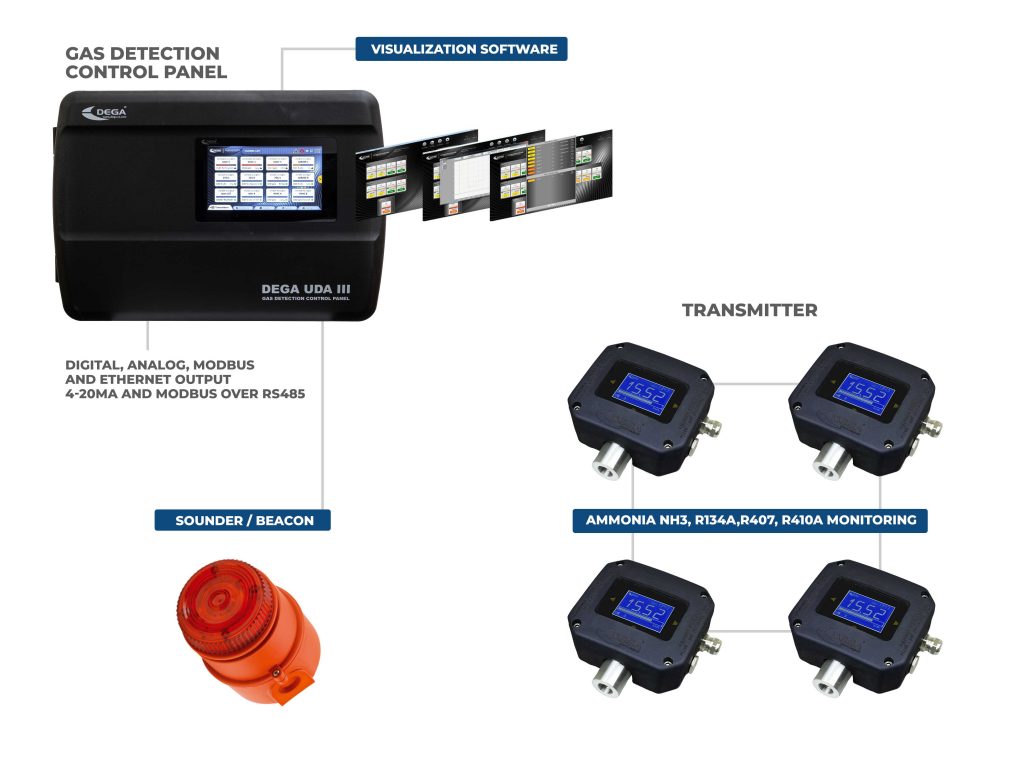

Common refrigerant gases such as NH3, R134a, R407 and R410a are used to maintain the cooling effect of air-conditioners, refrigerators, chillers and freezers. These gases are toxic and can cause harmful consequences to personnel in any areas where there is a potential of leakages from commercial storage vessels, air conditioning units, industrial refrigerators and freezers. To reduce exposure limits to the refrigerant gases we install our sensors to monitor for leakages and general atmosphere detection at low ppm levels, to ensure a rising or potentially dangerous environment by signalling sounder/beacons to activate, so that prompt action can be taken. Whether that be extraction fans or internal alarm systems to be mobilised. Monitoring for refrigerant leaks is also a way to ensure that you aren’t wasting gas which is also a commercial concern.

refrigerant room types Monitored

- Process Refrigeration

- Transport Refrigeration

- Air Conditioning Plants

- Ice Production

- Drying Plants

- Fresh water Installations

- Supermarkets

- Freeze-Drying

- Food Conservation

Direct Connection to the Plant or Control Panel

Our fixed gas detectors can be connected directly to the plant or factory alarms system to make sure that the refrigerated areas can be continuously monitored for the gas type level statuses. We also connected our Refrigerant Gas Monitoring systems to audio visual pre alarm indicators, including sounder/beacons. All our equipment is IEXEx certified so that you rest assured you are compliant with all the refrigerant room regulations, such as the AS 2865-2009 Confined spaces framework.

Personal Gas Detection Solutions

We also supply PPE personal gas detectors so that the confined space atmosphere can be monitored for all problematic gas types, these are IP68 and have 3 years continuous use with no need for charging. This gives the user peace of mind as with this long lifespan without charging means the detector is always ready.

REFRIGERANT PLANT ROOM GAS Monitoring Systems Products

Site analysis and system engineering

Each project starts with consultation on our clients requirements. JWII then design a Gas Detection System to meet the project needs

Service and maintenance

Our service team can provide comprehensive field service as well as workshop repairs. We can also help you plan the maintenance of your devices with a periodic maintenance contract.

Site Installation

Our in house technical team can assist you in the installation and commissioning of your gas detection system. From physical mounting to connection and start up.

Calibration Services

Our calibration facility offers you peace of mind that your gas detection system is operating to specification. We can carry our field calibration as part of your service contract or in house calibration at our facility.

Discover all type of applications

We also have IECEx certification so you can be confident that we conform with all necessary legislation and regulations.